Nano-Coating of Copper

Indice

Nano-Coating of Copper

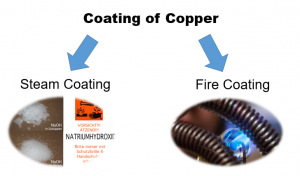

The base material for the coating is copper in any form. The coating is carried out either chemically by etching (steam coating with NaOH) or thermally by heating (Fire Coating by gas burner). During the coating process "gaps between the [outer most layers of copper] atoms" are created. The coating is often referred to as nano-coating, the layers of which build up during the process of the creation of the coating.

Nano-Coating Using NaOH

In order to coat copper wires or plates, you will need:

- A plastic container with lid (not too big)

- Weights for weighing down the lid

- Ready-wound copper coil, wires or plates

- ~ 100 grams of pure NaOH powder or beads (Do not use drain cleaners. You can buy it in art shops; it is used to remove paint as alkaline-based stripper, or in chemist's/drugstore)

- ~ 2 liters of distilled water (according to the quantity of coils and size of the plastic container)

- Electric kettle or stove top to boil water

Phase 1: Caustic bath (~ 2 days)

This first stage prepares the materials for the steam coating process:

- A zinc grid (can be a mesh, which is zinc coated) is placed at the bottom of the plastic container.

- Scatter just enough NaOH powder to cover the entire bottom of the container.

- Before placing the plates in the container, you can drill a small hole at the top corners of the plate(s) which will be used in Phase 2.

- Place the coils and/or plates directly on the mesh (the coils and/or plates sit on the grid so as to not touch plastic).

- Place the lid, slightly askew, on the container. Leave a small opening.

- Boil distilled water and pour it (boiling) into the container via the opening until water covers all the coils and/or the plates.

- Quickly close the opening by placing the lid correctly on the container.

- If necessary, place a weight on the lid to ensure as little steam as possible escapes.

- Leave the container in this state for 24 hours.

Caution, during the pouring of boiling water, steam will escapes. Please wear protective glasses and protective gloves during this process.

Phase 2: Caustic Steam (~ 2 days)

- After 24 hours have passed, open the plastic container and remove the coils and/or plates. NOTE: Use tight fitting gloves (for example, medical) and lift the plates out by the edges or use a wire through the hole you drilled in the plates. Ensure to touch the coils/plates in ONLY one area when you need to lift them to prevent damaging the nano-coating. Leave the mesh in the container.

- You will notice that the coils/plates have turned black. This is the nano-coating.

- Remove the liquid from the container. (Caution - store or dispose of the liquid correctly)

- Hang the coils or plates, which were previously submerged in NaOH water, on copper wires (utilize the holes at the corners of the plates to hang the plates).

- The coils should hang roughly 2cm above the bottom of the container and should not touch the container walls, the mesh or the other coils or plates.

- The plates stand on the mesh, vertically, hung on wires.

- Place NaOH to cover the bottom of the container as in Phase 1.

- Place the lid askew.

- Boil distilled water and pour it boiling through the hole to a depth of roughly 1cm.

- Close and fasten the lid quickly to stop steam from escaping.

- Let stand for 2 days.

(Caution - Use protective glasses and protective gloves during this process).

Phase 3: Drying/draining (minimum 3-4 days)

- The coils and/or plates now begin the drying process.

- Pour most of the liquid out of the container. Leave a bit of the water in the container and leave it covered, not weighted.

- Every 6 hours, for the next 3 or 4 days, take a multimeter (set on mv) and touch the mesh with the negative pole and the copper plate with the positive pole at several positions to drain the plate(s) voltage.

- For coils, if its a double coil, touch the coil with the negative pole of a multimeter at the positive pole of the coil and touch the positive pole of the multimeter at the negative pole of the coil for a few seconds, to drain the voltage out of the coil(s).

- When this process is completed, never touch the nano-coating and ensure the coils and/or plates never touch each other.

You can watch this process again on this Official Youtube Video from the Spaceshipinstitute: